When a critical need emerges, how quickly can a solution be developed? How quickly should a solution be developed, if it addresses a medical rarity? At MICRO-TECH, we believe that no clinical gap is too small. This was what spurred us to develop the world’s first carina Y-stent system for a single patient in 2005 – in just a week, no less.

An unfinished product and a pressing need

The story actually began a year earlier in 2004, when German physician Prof Peter C. Bauer came across our Y-stent prototype during a routine product presentation. Although the stent’s delivery/deployment system was still incomplete at that time, its concept and potential left a deep impression on him. Around a year later, Prof Bauer encountered a 42-year-old patient who had suffered a collapsed trachea from a car accident. The injury was debilitating – while survival was no issue, he would need to use a ventilator permanently. This was unacceptable to Prof Bauer, as it would tether the relatively young patient to a power source for the rest of his life.

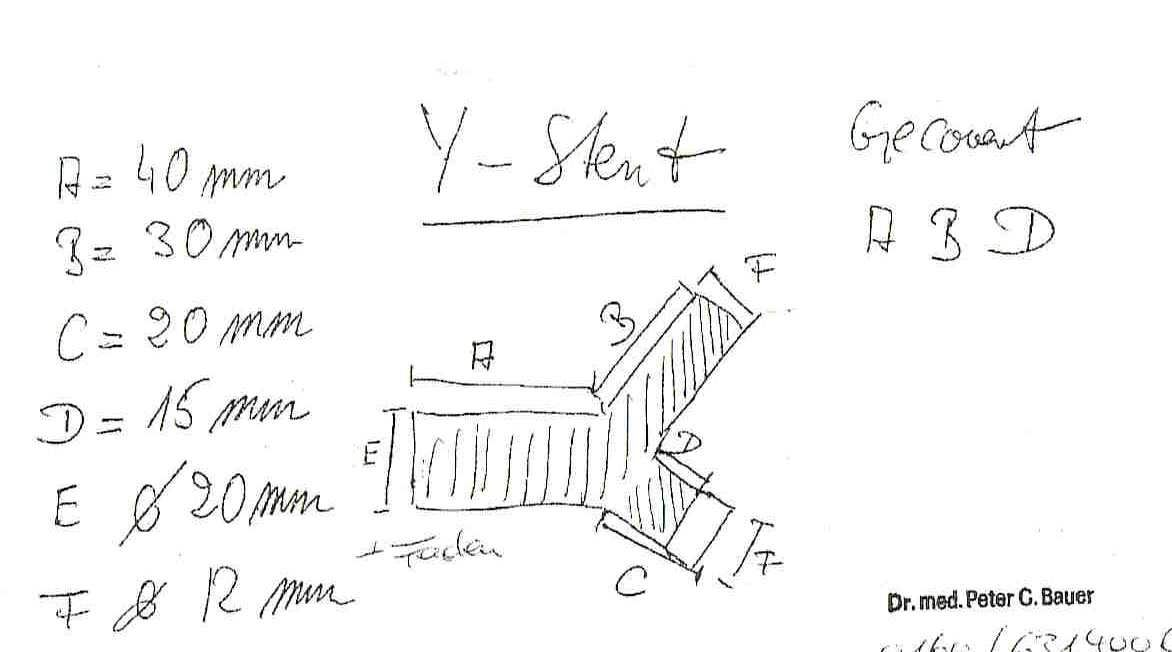

Prof Bauer reached out to Mr Derong Leng, then a MICRO-TECH director (now CEO), to explore a potential solution. Attached within his email was a sketch of the Y-stent that he had seen a year ago, with dimensions specific to the patient. It was essential to have this Y-stent – the patient presented with tracheal leak at the carina, where the windpipe splits into the left and right bronchi, so using multiple straight stents would support the collapsed trachea structurally but fail to address the airway leak.

At this point, the Y-stent was still far from complete, as its delivery/deployment system had not been designed yet, and development was on hold to prioritise other products. “From a business perspective, the correct thing to do back then was probably to turn Dr Bauer down, given the unproven market potential of the Y-stent at that time,” mused Mr Leng. “But he was fiercely insistent, and kept telling us, ‘You have to give it a try.’ This determination to improve one patient’s life was what inspired us to give it a go – Dr Bauer’s patient-centric mindset reminded me of why we founded MICRO-TECH in the first place.”

A solution within a week

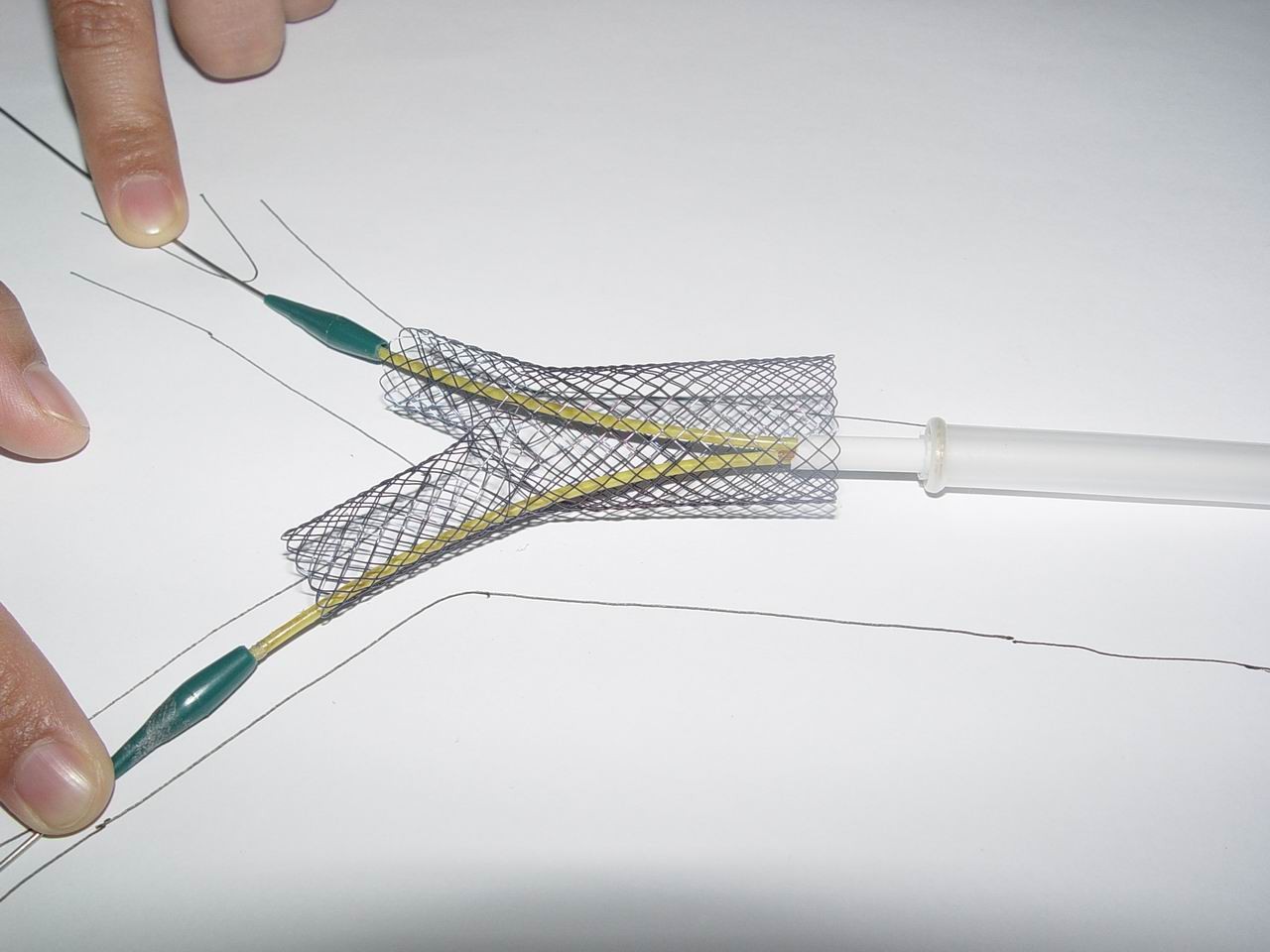

What followed were three days of intense brainstorming, design, and prototyping work, as Mr Leng and his team worked to create such a system from scratch. Everyone understood that time was of the essence – the patient did not have the luxury of waiting months to years for a protracted R&D process typical of medical device development. Still, there were demanding technical hurdles to overcome. Compared to a straight stent or J-stent, the Y-stent’s complex structure makes delivery and deployment very challenging. Accurately positioning it within the trachea right at the carina was another critical requirement.

The team came through after just three days with a novel delivery/deployment system for the Y-stent. It featured a crucial innovation: a staggered release mechanism that deployed the stent in stages with a hybrid system that uses a sheath and constraining threads for different sections of the stent. Curiously, its inspiration came from the most unexpected place. “The idea actually came to me in a dream in the middle of the night,” Mr Leng shared. “Of course, it was too late to suggest to the team at that time, so I put it off to the next morning. We got a prototype ready quite quickly after, and it barely just worked, but we knew we were on the right track.”

Operating this system was straightforward. With the stent in position, the two branches of the Y-stent that were in the left and right bronchi were released first, which created an expanded V-shaped structure that held the stent in position. Once done, the third branch of the stent – located in the trachea – would then be deployed to complete the procedure. Despite having a more complex release mechanism, the delivery/deployment system maintained excellent ergonomics and user-friendliness, with all its controls integrated into a single handle. Since it also relied on the double-guidewire technique that doctors are familiar with, adapting to the new equipment also took less time and effort.

Despite its lower learning curve, the Y-stent was not quite a plug-and-play solution. The team at MICRO-TECH recognised this, and the importance of clinical training for the newly-developed device – especially its deployment system. For that, there was Mr Daniel Kuhn, Senior Vice President and Regional President of MICRO-TECH EMEA, who was then leading the sales and marketing efforts for MICRO-TECH products in Europe. Given the urgency of the matter and the novelty of the Y-stent, Mr Kuhn took it upon himself to personally liaise with the Prof Bauer and his surgical team. As the anchor person for MICRO-TECH in Europe, he provided the necessary training and product demonstrations to them, while also facilitating the feedback and product refinement process.

A week after sending his email, Prof Bauer received the Y-stent and delivery/deployment system from MICRO-TECH. With Prof Bauer’s feedback on this prototype, the team at MICRO-TECH refined the system and delivered a second Y-stent a week later. It worked perfectly, and made medical history by being the world’s first integrated carina Y-stent.

A key milestone

Prof Bauer’s pioneering work in this area has benefitted many others since then, with the Y-stent becoming a core product within MICRO-TECH’s portfolio. Reflecting on its development, Mr Leng noted how the experience influenced the company’s approach in the decades ahead. “That was a defining moment for us at MICRO-TECH,” shared Mr Leng. “To be honest, the Y-stent’s applications are limited because it fills a very specific clinical niche. But that chapter has shaped how we work even today.”

He continues, “On one hand, its success boosted our European colleagues’ confidence in our ability to support them through R&D and novel solutions. In fact, Daniel started introducing me as Mr Solution to his contacts! (laughs) Conversely, the team in China was extremely grateful for this opportunity created by their European counterparts, and for their support in managing the client’s requests. These changes in perception paved the way for deeper collaboration, and shortly after the establishment of MICRO-TECH Europe.”

He continues, “Externally, our collaboration with Dr Bauer laid the foundation for partnering closely with clinicians in every stage of product development. Achieving a working product in just three days is not easy at all, and it really showed us what’s possible when expertise and purpose align.”

10486-resized-1.jpg)