Mention “innovation” or “R&D,” and most people picture specialised teams of designers and engineers working in the early stages of a product’s lifecycle, then handing it off to the sales, marketing, and commercial teams. But what if the people driving innovation were also product owners who share directly in the revenue that their ideas and work generate? Such a model is almost unheard of, but it’s a key feature of our Innovation Partner Program at MICRO-TECH, which crowdsources ideas from employees, formalises them into R&D projects, then rewards the teams involved via post-commercialisation profit sharing.

Through the program, we’ve developed some of our most successful products, including our Endoscopic Submucosal Dissection (ESD) knife. This instrument started off as an employee’s idea based on his understanding of surgeons’ needs and, through his efforts, became a first-in-class device that remains unique on the market today. It’s a powerful reminder of what’s possible when innovators are given the agency to shape and share in the value they create.

Mr Derong Leng, MICRO-TECH’s CEO, gives his insights and reflections on the program in the interview below.

How did the idea for creating the Innovation Partner Program come about?

The original intent was two-fold. The first was to align the interests between MICRO-TECH and its employees through profit-sharing. If we can incentivise employee to actively identify market gaps, then work on projects to fill these gaps, then it’s win-win for both MICRO-TECH and the employee.

On a deeper level, we also wanted to empower our employees who have an entrepreneurial streak. Typically, these employees will either leave us to start their own business or, if they lack the necessary resources, do nothing. Neither outcome is ideal, obviously, plus there are various risks that they must bear when starting their businesses. The Innovation Partner Program offers an alternative: employees can explore their ideas in a significantly derisked way, while we retain such talent and support their ambitions.

What were the considerations that the senior management had when the program was being designed? Was it difficult to draw up the initial framework given its uniqueness?

We’ve run similar schemes with doctors, so we just needed to adapt the program for internal employees. It comes back to MICRO-TECH’s principle of driving innovation through partnerships while treating our partners fairly, and this program is an extension of that.

Of course, there were some considerations, like how we could encourage participation. For that, we decided that anyone can be a principal investigator, from a salesperson who has identified a clinical need to an engineer who sees an adjacent application for a technology. The project lead is also free to assemble their own team.

Another program feature that we decided on was a cap on the profit-sharing period: 5 years following a product’s launch. This would be fair to the team while also encouraging them to take on other projects to keep a streak going.

How does MICRO-TECH decide on resource allocation to support these projects? What considerations are there?

Every R&D project is assessed on its own merits by our scientific committee first, before approved ones are launched. In that sense, projects don’t compete against each other for resources. Of course, this doesn’t mean that there’s zero competition. If two projects that are focused on the same general area, I suppose there could be some degree of rivalry in, for example, developing a superior product.

What was the first R&D project under the Innovation Partner Program?

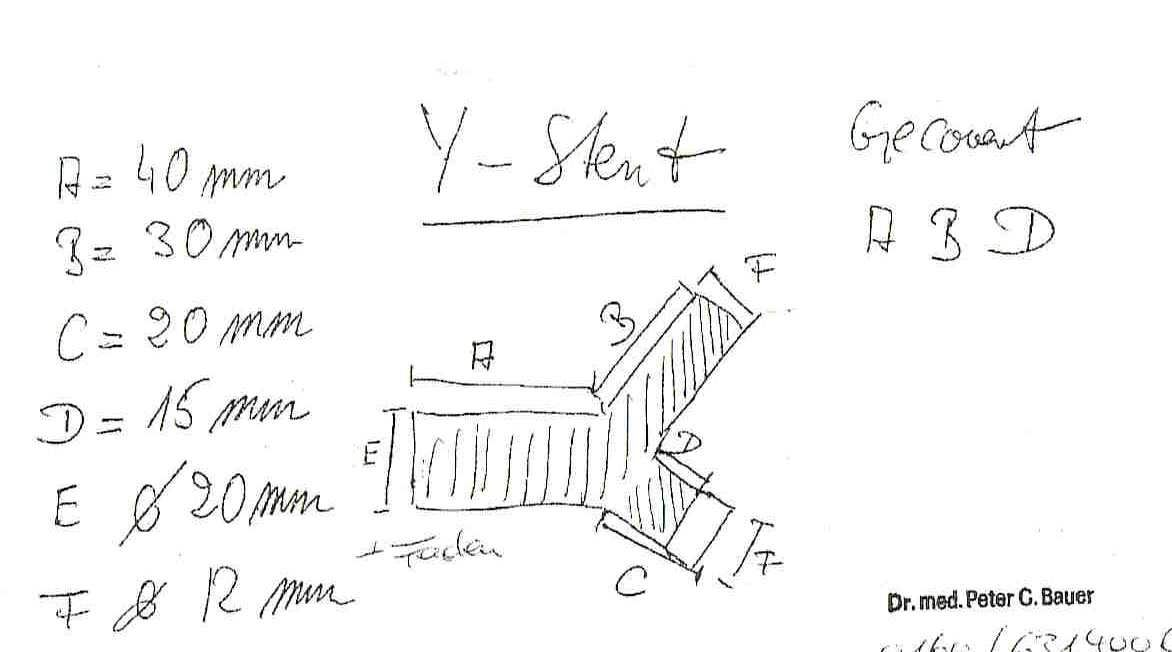

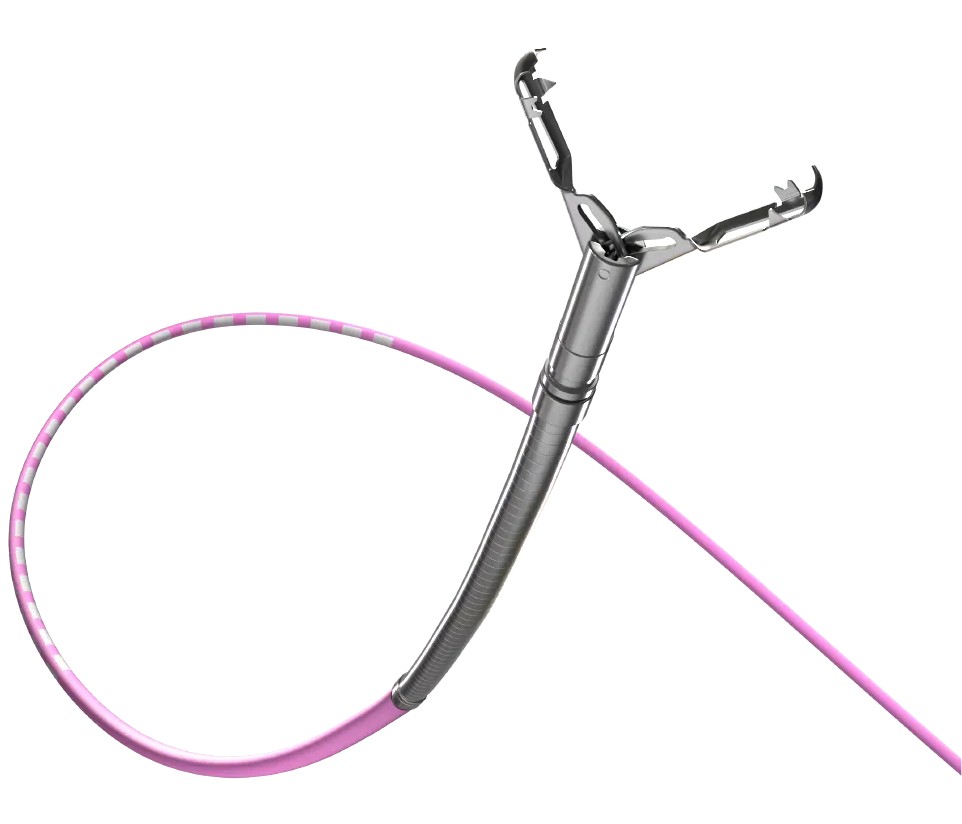

That will be our ESD [Endoscopic Submucosal Dissection] knife. The idea for it was actually suggested by an employee before the Innovation Partner Program was announced – his concept was a 2-in-1 system that combined an electrosurgical knife with a water jet, so surgeons can make incisions and perform saline injections using a single instrument. When the program was launched, we encouraged him to develop the idea further, so he submitted a formal proposal and got the approval to proceed.

The product was completed after nearly two years of development. As a 2-in-1 solution, our ESD knife reduces instrument changes during surgery, which makes procedures much more efficient. It quickly became a halo product, and I’m proud to say that it remains unique in the market even today, in terms of overall functionality and ease of use. This product line is still evolving – we have been iterating on it in partnership with a Chinese university, and expect the improved version to receive regulatory approval in 2026.

Were there any surprises that resulted from this program?

One of the biggest surprises for us was realising that even a product that seems “perfect” can be further improved thanks to our employees’ ingenuity and commitment. We saw this with the LOCKADO haemostasis clip, which we had developed with heavy R&D to outperform other offerings in the market at a more aggressive price.

The LOCKADO performed exceptionally well commercially, and its story could have ended there, but some employees proposed to refine it with “SD [Special Design]” variants that further improve on the original. Since some of the ideas were independently raised, they were parked under the Innovation Partner Program.

What impressed me just as much as the innovations themselves was the dedication behind them. During that period, MICRO-TECH was preparing for its public listing, so some resources that were normally available were temporarily on hold. Instead of waiting, the team stepped up and filled those gaps themselves, even taking on tasks like IP research. It was heartening to see our co-workers pushing the technical boundaries of what we can achieve – on their own initiative and sometimes at their own expense, no less.

Looking back at this program, what do you think has been its biggest impact so far?

Beyond the obvious, such as new products and top-line growth, I think the program has helped MICRO-TECH to meaningfully engage with its most innovative employees. Projects under the Innovation Partner Program are undertaken as “extra” work, so they demand additional time and effort from the teams, who must pull first identify a problem, then pull resources together to develop a solution. Through this program, however, we’ve created a system for these employees to showcase what they are capable of – and be properly rewarded. This is a deep level of engagement that will be difficult to achieve elsewhere.

What’s next for the Innovation Partner Program?

We’ve seen strong success with this program, and it effectively complements MICRO-TECH’s core R&D efforts, so we will continue to leverage it as a platform to source for new ideas. Currently, we have three to four of such projects in the pipeline. We are monitoring their progress, while keeping the door open for new ideas and proposals in the future.

10486-resized-1.jpg)